It’s officially fall, but there’s still time to apply sealer in many parts of the country. Perhaps you’re accustomed to refined tar sealers. Or, maybe you like to use asphalt emulsion-based sealers. While both products are very effective, there is another option available. Here are five reasons why you should re-think your pavement sealer product selection prior to your next project.

5 Reasons to Re-Think

- Get the best of both worlds. Refined tar sealers are increasingly under scrutiny – despite a growing body of science which supports their safe use. As a result, everyone seems to want an alternative to coal tar, yet still have all the same benefits. For that reason, GemSeal developed Black Diamond™, a sealer that combines the performance of refined tar sealers with the benefits of asphalt-based sealers.

- Apply with confidence. Like our other quality pavement products, GemSeal manufactures Black Diamond using a colloid mill process, not a batch process, to ensure consistency. It was tested for over two years before entering the market at the beginning of 2014. And, samples continue to be evaluated hourly and daily at each of our plant-operated labs.

- Avoid application restrictions. Black Diamond contains zero refined tar, making it acceptable for use in many areas that have banned coal tar.

- Provide better coverage and superior color stability.

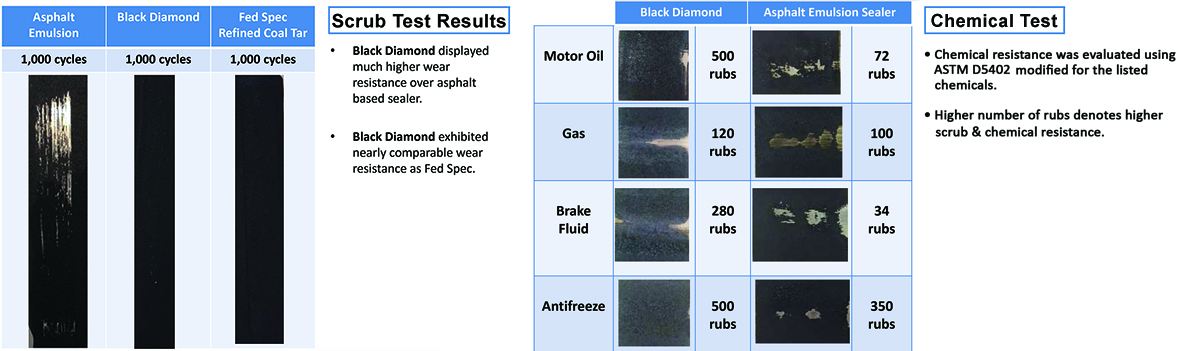

Black Diamond is more durable than asphalt emulsion (it wears 2-3 times longer than traditional asphalt emulsion sealers), provides better coverage, and improves chemical resistance over standard asphalt emulsion sealer. Plus, its natural pigment resists oxidation enabling superior color stability. Black Diamond also provides performance closer to refined tar sealers through ease of application, fuel resistance, and toughness against power steering marks.

- Satisfy your crews and clients. Crews love working with it because there is no irritation due to its unique chemistry (nearly zero VOC). It can be applied at lower outside temperatures, has a better coverage rate, and a higher dilution rate than most traditional asphalt emulsion sealers, which saves money for you and your clients.

Additional literature or videos are available for download or you may contact your local GemSeal sales representative.

Lee F. Lowis /

Oct 1 , 2018

Lee F. Lowis /

Oct 1 , 2018